News

Recommended Products

Contact Us

Contact Person: Cindy Zhu

TEL:+86 13418453374

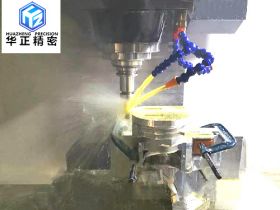

How to prevent wear when machining precision parts?

The common wear types of precision parts processing mainly include run-close wear, hard particle wear, surface fatigue wear, hot surface wear, phase change wear and fluid dynamic wear.

Running and closing wear is the wear of machinery under normal load, speed and lubrication conditions, this wear generally develops slowly, and has little impact on processing quality in the short term. Hard particle wear is due to the part itself dropped abrasive particles or hard particles from the outside into the machine tool, mixed into the processing area, by mechanical cutting or grinding, causing damage to the parts, which has a serious impact on the quality of processing.

Fatigue wear on the surface of precision parts is the mechanical under the action of alternating loads, resulting in tiny cracks or ban-dot-like pits, resulting in damage to parts. This type of wear is usually closely related to factors such as pressure size, load characteristics, machine material, size and so on.

Thermal wear is the heat generated by the parts during the friction process acting on the parts, so that the parts have tempering softening, burning and wrinkling and other phenomena. This type of wear usually occurs in high-speed and high-pressure sliding friction, the wear is relatively destructive, and accompanied by the nature of accidental wear.

Corrosion wear is a chemical action, that is, chemical corrosion causes wear. When the surface of the part is in contact with acid, alkali, salt liquid or harmful gas, it will be subjected to chemical attack, or the surface of the part will be combined with oxygen to produce a hard and brittle metal oxide that is easy to fall off and wear the part.Phase change wear is a long-term part in the high temperature state work, the surface of the part metal tissue grain heat becomes larger, the grain boundary around the oxidation, resulting in a small gap, so that the part is fragile, wear resistance decreases, resulting in part wear.

Prev: What are the processing equipment and technologies in CNC machining centers?

Next: How to improve the finish of CNC four-axis machining?

Back